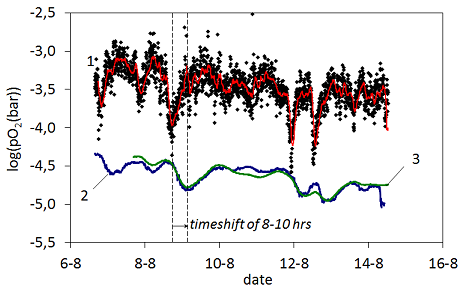

A simultaneous measurement of the glass melt redox in the bath charging area (red line, a 1 hour moving average) and of the glass melt redox in the feeder channel (blue line) was performed. It is shown that distinct redox dips in the batch area (caused by individual “dirty“ cullet batches) appeared 8 to 10 hours later as less pronounced dips in the feeder as a result of glass melt mixing in the melting tank.

cc

From the simultaneous measurement the residence time of the glass melt in the melting tank can be calculated. Knowing the residence time, the redox state in of the melt in the feeder (and that of the glas product) can be predicted 10 hours in advance (green line), showing the enormous potential of the batch sensor for an effective and fast redox control loop.

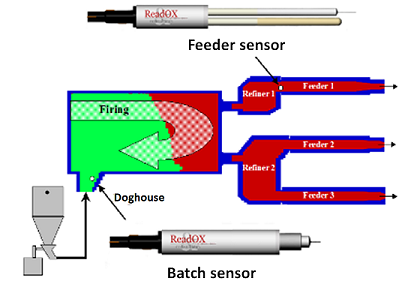

Read-Ox develops a so-called batch redox sensor for the in-line measurement of the redox state of the glass melt in the batch charging area.

Read-Ox develops a so-called batch redox sensor for the in-line measurement of the redox state of the glass melt in the batch charging area.