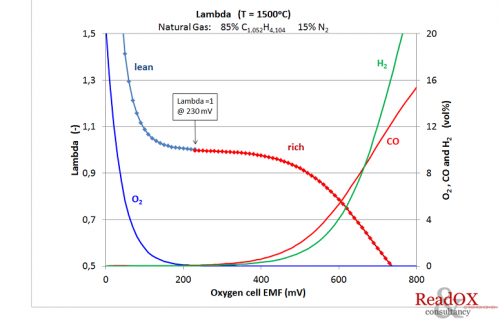

Usually, the air-fuel ratio (or lambda) of the combustion space in the glass tank is set close to unity. Energy efficiency is highest at lambda=1. A too oxidized (lean) atmosphere will lead to high NOx levels and a too reduced (rich) atmosphere will lead to too high levels of CO in the flue gasses, both species being harmful to the environment. Additionally, too high CO levels in the combustion space may lead to damage to the refractory and/or overheating of the regenerator and stack area by post combustion. Also glass quality may be affected by a too reduced or too oxidized atmosphere.

The lambda value of the combustion atmosphere can be calculated from the oxygen sensor's EMF mV-signal and the atmosphere temperature. For an accurate calculation of lambda from the oxygen sensor signals, the precise fuel composition (e.g., CnHm and N2 content), as well as the humidity of the combustion air should be known.

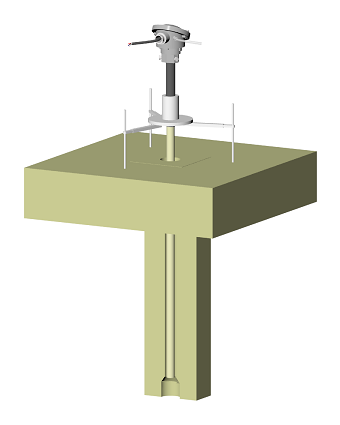

Besides the more specialized glass melt and tin bath oxygen sensors, Read-Ox also supplies the “classic” oxygen sensor for the combustion space, regenerator or flue gas channel. Based on the Nernst Equation, it measures the oxygen activity of the atmosphere from which %O2 and/or the lambda value is calculated for

Besides the more specialized glass melt and tin bath oxygen sensors, Read-Ox also supplies the “classic” oxygen sensor for the combustion space, regenerator or flue gas channel. Based on the Nernst Equation, it measures the oxygen activity of the atmosphere from which %O2 and/or the lambda value is calculated for