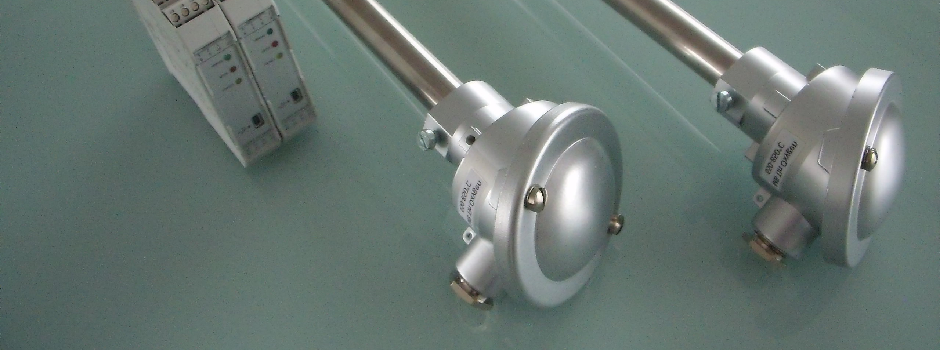

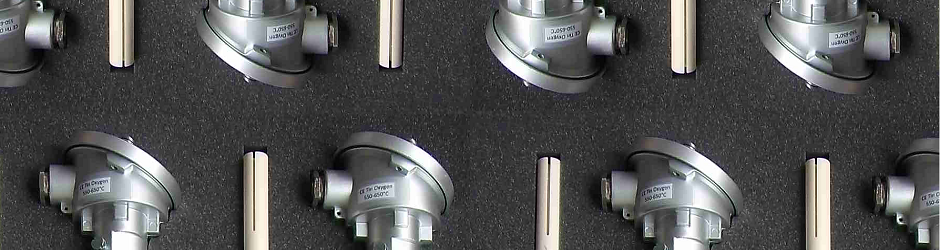

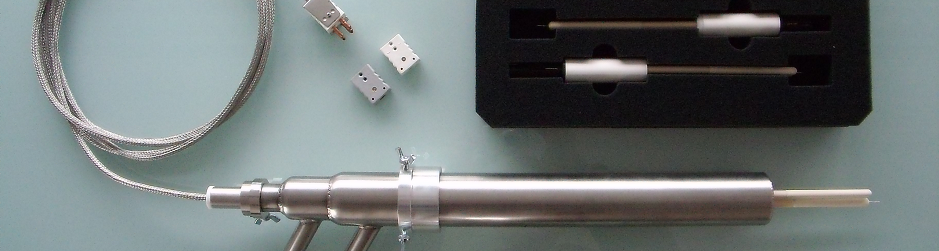

Read-Ox & Consultancy B.V., started in 2001, is specialised in the production of oxygen sensors for the glass industry. These oxygen sensors are based on the electrochemical cell principle and are able to measure the oxygen activity of the glass melt (in feeder channel, forehearth or canal) or combustion atmosphere (regenerator crown or flue gas channel) in the industrial glass production furnace. Additionally, for the float glass production line we have special oxygen sensors for the tin bath, for inside the molten tin or for in the tin bath protective atmosphere.

Relying on its broad experience in the field of oxygen activity measurements in glass industry, Read-Ox may offer tailor made solutions for various furnace designs.

Learn more about us